In 2025, the welding industry is undergoing a profound transformation from exquisite craftsmanship to intelligent manufacturing. The spirit of "Great Power Craftsmen" converges and integrates with artificial intelligence technology, jointly propelling the industry to new heights.

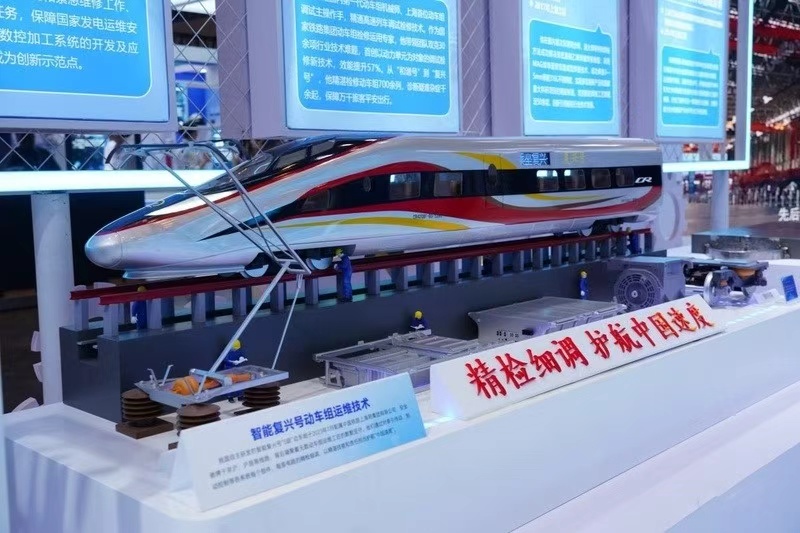

Represented by craftsmen like Wang Hai and Wang Hongxiao, the "Great Power Craftsmen" adhere to the "zero-defect" standard, condensing decades of experience into every precision weld. They have provided reliable guarantees for national pillars such as high-speed railways and wind power. Beyond inheriting the ultimate craftsmanship, they have also transformed practical experience into digital process packages, laying a solid data foundation for intelligent development.

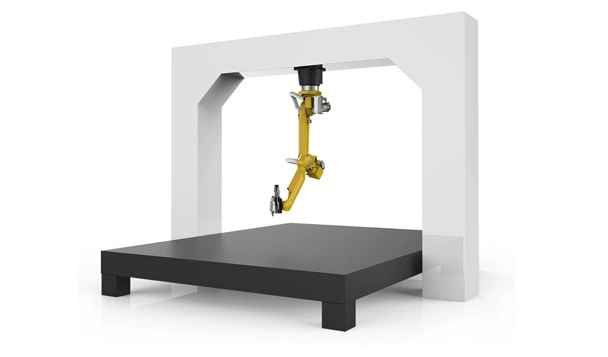

Meanwhile, AI technology is deeply empowering the entire welding process. Equipped with high-precision visual recognition and adaptive control systems, welding robots, such as MINGHUA's friction stir welding robot series, can independently identify weld seams and adjust parameters in real time, achieving intelligent responses to diverse working conditions. AI has also upgraded quality control from "post-production random inspection" to "online real-time diagnosis," enabling timely intervention before defects occur and driving production toward full-cycle precise management.

Today, the craftsman spirit forms the industry's foundation, while AI technology injects intelligent momentum into it. The welding field is stepping into a new era of higher efficiency and precision through the collaboration between human experience and data-driven intelligence.