With the rapid development of the aerospace industry, there is an increasing demand for high-precision and high-efficiency processing equipment. To meet this demand, a series of high-performance 5-axis CNC machines have been developed, covering two categories: cradle machining centers and gantry machining centers, designed for the machining of complex structural parts in aerospace.

The five-axis cradle machining center is available in six sizes, with an outer diameter ranging from Φ400 to Φ1000mm, and is equipped with a high-performance motor spindle with a maximum speed of 18000r/min. Its oscillating axis positioning accuracy is up to 0.01mm, XYZ axis repeat positioning accuracy is up to 0.003mm, and turntable repeat positioning accuracy is up to 0.005mm, ensuring high-precision machining needs.

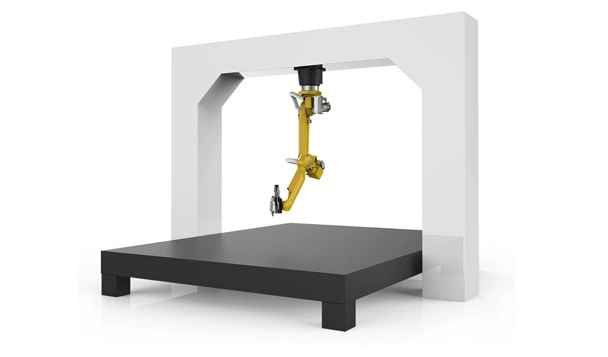

The series of 5-axis gantry machining centers includes fixed beam, moving beam and moving column structures, and the equipment specifications are extended from 2 meters to 40 meters, which is suitable for the processing of workpieces of different sizes. The spindle speed range is from 4500r/min to 24000r/min, and the repeated positioning accuracy of A/C axis is up to 0.004mm, and the repeated positioning accuracy of XYZ axis is up to 0.005mm. At the same time, the brake torque of the heavy-duty pendulum shaft is up to 20,000Nm, and the spindle torque is up to 1,000Nm, which meets the needs of high-strength cutting.

This series of machine tools are mainly equipped with domestic CNC systems, which are suitable for precision machining of aerospace structural parts such as high-temperature alloy steel, titanium alloy, aluminum alloy, ceramics and carbon fiber composite materials. It has performed well in mass production, for example, it has invested 19 five-axis gantry machining centers to expand the production line of large aircraft structural parts at one time, and quickly achieved stable mass production.

In addition, for the optimization of the assembly process of large aircraft, a digital assembly production line has been developed, integrating automatic drilling and riveting, gluing, grinding, cleaning and other processes. Among them, the innovative skin subsidence milling technology has been successfully applied to the mass production of double-curvature fuselage skin, significantly improving the assembly efficiency and quality.

These high-precision and high-reliability processing equipment provide strong technical support for aerospace manufacturing and promote the development of the industry in the direction of intelligence and efficiency.