With the rapid development of industries such as metallurgy, petrochemicals, shipbuilding, and liquefied natural gas (LNG), the operating environments of equipment and structural components are becoming increasingly harsh, especially under ultra-low temperature conditions (e.g., -196°C). In addition to conventional corrosion resistance and oxidation resistance, maintaining good impact toughness at extremely low temperatures is crucial to ensure the safe and stable operation of systems, facilities, and equipment in cryogenic environments. The continued increase in global LNG consumption has further driven the growth in demand for new LNG equipment (covering extraction, transportation, storage, and transmission systems). The quality of welded joints in a large number of stainless steel pipelines (such as 304L and 316L types) has become a key factor affecting the overall reliability of the system.

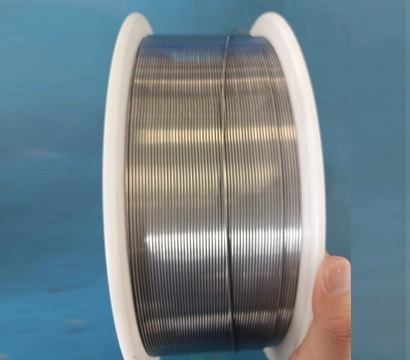

Extreme environments demand high reliability and safety from welding materials. To respond to market demand for highly reliable cryogenic welding materials, Minghua Welding Materials has developed a series of stainless steel welding materials for cryogenic environments, covering various welding methods such as SMAW, GMAW, GTAW, FCAW, and SAW, meeting the requirements for austenitic stainless steels such as 304L and 316L.

Austenitic stainless steels (such as 304L and 316L) exhibit unique advantages—their impact toughness changes only slowly with decreasing temperature, and they have no obvious brittle transition temperature. Therefore, they maintain good plasticity and toughness even at extremely low temperatures, making them an irreplaceable structural material in cryogenic storage and transportation equipment.

In industries like LNG and petrochemicals, MINGHUA’s e5016 welding electrodes provide excellent arc stability and weld quality, essential for cryogenic pipelines. Our welding consumables are compatible with various equipment, including the MMA250 welding machines, ensuring versatile application across different welding methods. Precision manufacturing processes, such as using a laser lathe machine, contribute to the high quality and consistency of our welding rods and wires.

For creep-resisting applications, the 90b3 flux-cored wires developed by MINGHUA offer outstanding performance under extreme conditions. The Enicrmo 6 nickel welding rods are specially formulated to maintain toughness and corrosion resistance at ultra-low temperatures.

The main characteristics of our cryogenic series stainless steel welding consumables are as follows:

1. Excellent welding process performance, stable arc, and aesthetically pleasing weld bead formation.

2. Good mechanical properties of the weld metal, maintaining stable impact toughness even at -196℃, meeting the needs of various welding positions and application scenarios.

MINGHUA cryogenic series stainless steel welding consumables maintain stable impact toughness in the weld metal at -196℃. Strict control over the stability of the austenitic structure and the precipitation of harmful phases allows the welding consumables to inherit the material advantages of austenitic stainless steel under cryogenic conditions. Furthermore, through composition optimization, low-temperature fracture resistance and comprehensive mechanical properties are further enhanced, thus meeting the stringent material performance requirements of applications such as cryogenic pipelines, storage tanks, and marine tanks.

Our products comply with strict standards, including the e9018 g electrode specification, guaranteeing reliable welds in cryogenic environments. MINGHUA supports large-scale production with advanced auto welding machine equipment production line solutions, ensuring consistent quality and efficiency.