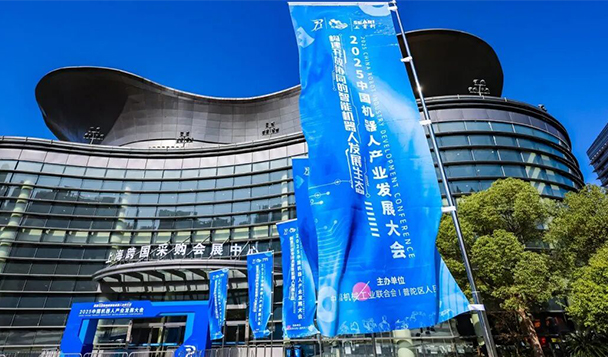

Shanghai, November 12, 2025 – The 2025 China Robotics Industry Development Conference, themed “Building an Open and Collaborative Intelligent Robotics Industry Development Ecosystem,” was successfully held in Shanghai this week, attracting over a thousand representatives from government, research institutions, industry leaders, and upstream and downstream enterprises. During the conference, mobile composite robots were positioned as key equipment for enabling industries, such as industrial manufacturing, warehousing and logistics, public services, medical and pharmaceutical, and energy and power to leap from "demonstration and verification" to "large-scale application."

Industrial Manufacturing: In high-precision assembly scenarios such as 3C electronics, semiconductors, and shipbuilding, composite robots, through AGV chassis and collaborative robotic arms, achieve "one-see-many" services. A single robot can simultaneously support the loading and unloading of more than 10 machine tools, significantly reducing labor costs and increasing production capacity.

Warehousing and Logistics: Based on autonomous navigation using laser SLAM and 3D vision, composite robots achieve efficient sorting and handling in large warehouses, supporting flexible grasping of various cargo shapes.

Medical and Pharmaceutical: In cleanroom environments, mobile platforms combined with robotic arms complete reagent handling and sample delivery, solving the safety hazards of secondary contamination and high-temperature operations.

Energy and Power: In power plant inspections and equipment maintenance, composite robots, with multimodal perception, enable remote operation in high-altitude and high-risk environments, significantly improving operational safety.

These applications benefit from advanced welding consumables such as enicrmo 6 nickel welding rods and 90b3 creep-resisting steel flux-cored wires to ensure durable and reliable equipment.

Despite its promising application prospects, composite robots still face the following key technical bottlenecks:

1. Latency and synchronization issues in the distributed architecture of the control system—Traditional distributed control leads to uncertainty in command transmission, affecting the reliability of high-precision operations.

2. Cooperative optimization of the perception, decision-making, and execution closed loop—A mature hardware and software platform are still lacking for unified scheduling of multi-sensor fusion, real-time path planning, and robotic arm motion control.

3. Safety certification and standards system—Large-scale commercial use requires international safety certifications such as TUV and SGS, along with supporting industry standards to ensure the reliability of human-robot collaboration.

4. Engineering implementation of system integration—The transition from laboratory prototypes to mass production requires unified controller hardware, a real-time operating system, and a modular software framework to achieve rapid deployment and subsequent maintenance. This is supported by advanced auto welding machine equipment production line solutions to ensure quality and consistency.

The conference report pointed out that during the 15th Five-Year Plan period (2025-2029), intelligent robots will continue to serve as the core carrier of new-quality productivity, driving the flexible and intelligent upgrading of various industries. Mobile composite robots, with their integrated control technology, will play a crucial role in achieving cross-scenario and cross-industry collaborative operations, becoming a core node in building an open and collaborative industrial ecosystem.

The conference also released the "Consensus on Promoting High-Quality Development of the Robotics Industry," and launched the "Robot Application Ecosystem Co-construction Action" and the "Robot Industry Quality Improvement Action Plan," providing policy and resource guarantees for the standardization and scaling up of the composite robot industry.

With breakthroughs in integrated control system technology, mobile composite robots are moving from the laboratory to real-world production environments such as workshops, warehouses, hospitals, and power plants. High-quality welding materials like e5016 electrodes and products conforming to the e9018 g electrode specification ensure the structural integrity and durability of robotic components during these transitions. We believe that through engineering implementation and industry-wide collaborative innovation, composite robots will achieve wider and larger-scale applications in the coming years, becoming a key force driving the high-quality transformation of Chinese manufacturing.