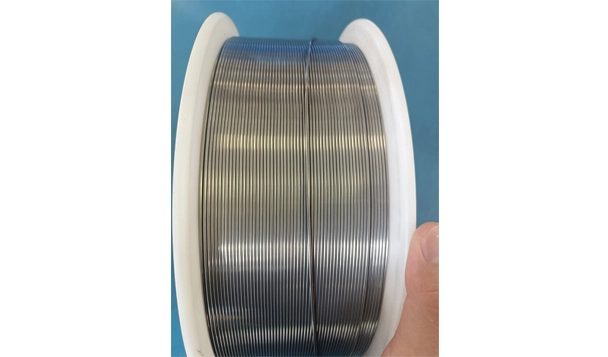

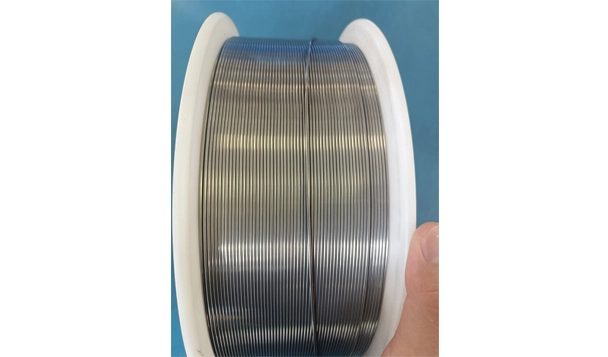

CO2 Gas Shielded Heat-Resistant Steel Flux-Cored Wire E81T1-B2C

It suitable for all position welding,for welding of high temperature and high pressure pipelines,

Synthetic chemical machinery and petroleum cracking equipment below 520℃.

It suitable for all position welding,for welding of high temperature and high pressure pipelines,

Synthetic chemical machinery and petroleum cracking equipment below 520℃.

Suitable for all position welding, soft and stable arc, less splash,

Beautiful forming, good slag removal, less smoke, with excellent welding process performance

Low temperature impact performance

| Chemical components of deposited metal (%) (shielding gas: CO2) | |||||||

| Item | C | Mn | Si | S | P | Cr | Mo |

| Example value | 0.055 | 0.8 | 0.22 | 0.005 | 0.012 | 1.13 | 0.51 |

| Mechanical properties of deposited metal (shielding gas: CO2) | |||||

| Item | Rm (MPa) | ReL/Rp0.2 (MPa) | A (%) | KV2 (J) | Heat treatment |

| 20℃ | |||||

| Example value | 644 | 556 | 22.5 | 70 | 690×1h |

| Diameter of welding wire (mm) | φ1.2 | |

| Current range | Flat welding | 120-300 |

| (A) | Upward vertical welding, overhead position welding | 120-260 |

| Vertical down welding | 200-300 | |

| Horizontal position welding | 120-280 | |