A robot laser welding machine is a cutting-edge technology that merges the precision of robotics with the efficiency of laser welding. This system is designed for high-speed, high-precision welding applications in various industries, including automotive, aerospace, electronics, and metalworking. By leveraging robotic arms and advanced laser technology, this machine offers superior control, faster production times, and enhanced weld quality. In this article, we will explore the definition, features, and advantages of the robot laser welding machine.

A robot laser welding machine is an automated system that uses a laser beam to melt and fuse materials, such as metals, with the help of a robotic arm. The robot arm provides precise movement and positioning of the laser, ensuring that the welding process is consistent and accurate. The laser is focused on a very fine point, producing a concentrated heat source that allows for deep penetration and high-quality welds.

The integration of robotics enables the robot laser welding machine to perform complex welding tasks, even in confined spaces or difficult-to-reach areas. It is equipped with sensors and controllers that allow the system to adjust parameters such as laser power, speed, and focus for optimal welding results.

The robot laser welding machine stands out due to its remarkable features, which make it an ideal choice for industries requiring high-quality welds. Below are some of the key features:

High Precision: The robotic arm's precise movement ensures consistent and accurate welding, reducing the risk of defects such as porosity, cracks, or misalignment.

Speed and Efficiency: Laser welding is known for its rapid process, which helps to shorten cycle times and increase production efficiency. This feature is particularly beneficial in mass production settings.

Automation: The robotic arm enables continuous operation with minimal human intervention. Once programmed, the robot laser welding machine can operate autonomously, reducing labor costs and human error.

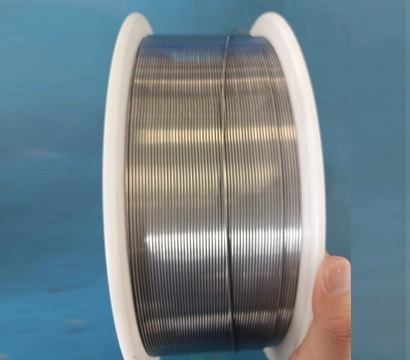

Versatility: The machine can handle a variety of materials, including stainless steel, aluminum, and titanium. It can weld thin and thick materials, providing flexibility in different manufacturing applications.

The robot laser welding machine offers several advantages that make it an essential tool in modern manufacturing processes. These benefits include:

Increased Productivity: The automation and high-speed welding capabilities reduce production time, allowing manufacturers to increase their output without sacrificing quality.

High-Quality Welds: The precision of the laser beam ensures that the welds are clean, smooth, and strong, with minimal heat distortion or deformation.

Reduced Operational Costs: With minimal human involvement and faster processing times, companies can save on labor and material costs. Additionally, the precision of the welds reduces the need for rework or repairs.

Customization: The machine can be easily adjusted to accommodate different materials, weld types, and geometries, making it suitable for a wide range of applications.

The automatic welding line is used across various industries where high precision and efficiency are critical. Some of the key applications include:

Automotive Industry: Used for welding critical components, such as car body parts and engine components, where strength and accuracy are essential.

Aerospace: Ideal for welding lightweight metals, such as aluminum and titanium, for aircraft components.

Electronics: Employed for soldering and welding tiny components on circuit boards, ensuring precise and reliable connections.

Medical Devices: Utilized for welding small, complex parts in medical equipment, requiring high-quality, sterile welds.

| Feature | Advantage |

|---|---|

| Precision | Ensures consistent, high-quality welds |

| Speed | Increases production efficiency and reduces cycle times |

| Automation | Lowers labor costs and reduces human error |

| Versatility | Capable of welding various materials and thicknesses |

The robot laser welding machine is an advanced solution for industries seeking precision, speed, and cost-efficiency in their welding processes. Its integration of robotic automation with laser welding technology offers unmatched accuracy, reliability, and versatility. With its high-speed performance, minimal operational costs, and ability to produce high-quality welds, the robot laser welding machine is revolutionizing modern manufacturing.