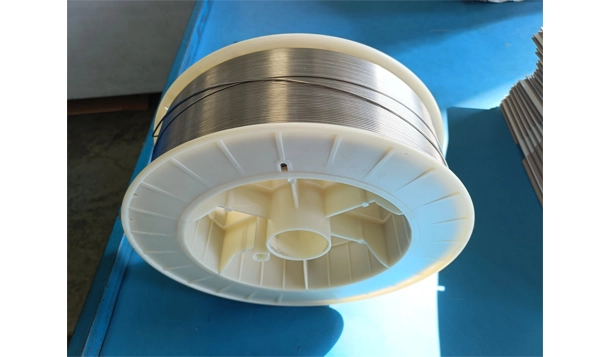

E81T1-W2C Resistance Steel Fluxed Cored Wire

Titanium oxide type CO2 gas shielded weather-resistant steel welding wire with flux core. good welding effient, beautiful appearance.

Titanium oxide type CO2 gas shielded weather-resistant steel welding wire with flux core. good welding effient, beautiful appearance.

It is permitted for all-position welding.

The welding efficiency is high.

The deposited metal has excellent atmospheric corrosion resistance.

Commonly used in the fields such as bridges, rail transit and rolling stock.

| Chemical components of deposited metal (%) (shielding gas: CO2) | ||||||||

| Item | C | Si | Mn | S | P | Ni | Cr | Cu |

| Example value | 0.04 | 0.4 | 1.2 | 0.008 | 0.012 | 0.64 | 0.5 | 0.38 |

| Mechanical properties of deposited metal (shielding gas: CO2) | ||||

| Test item | Rm (MPa) | ReL/Rp0.2 (MPa) | A (%) | KV2 (J) |

| -40℃ | ||||

| Example value | 610 | 540 | 24 | 90 |

| Reference current (DC+) | ||||

| Diameter of welding wire (mm) | φ1.2 | φ1.4 | φ1.6 | |

| Current range | Flat welding | 120-300 | 150-400 | 180-450 |

| (A) | Vertical upward welding and overhead position welding | 120-260 | 150-270 | 180-280 |

| Vertical down welding | 200-300 | 220-300 | 250-300 | |

| Horizontal position welding | 120-280 | 150-320 | 180-350 | |