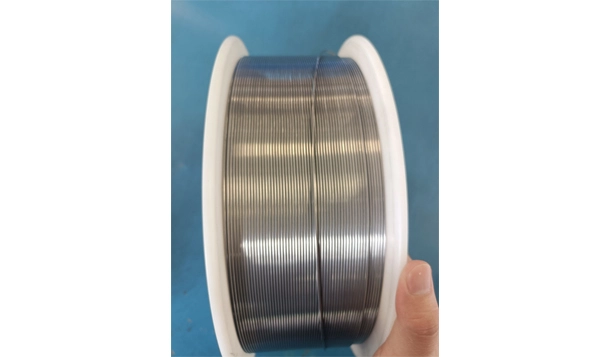

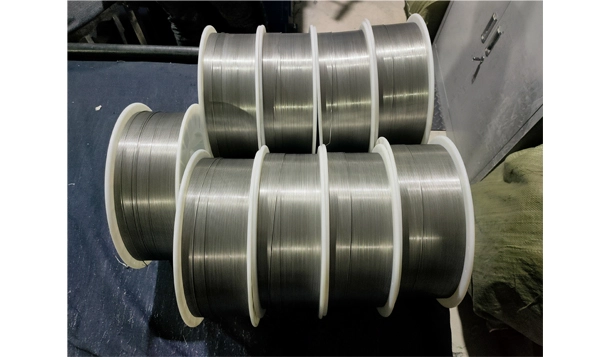

Stainless steel flux cored welding wire is a highly regarded material in the welding industry due to its durability, strength, and versatility. It is specifically designed to provide superior welding performance, especially in demanding environments. This type of welding wire is ideal for use in industries such as construction, automotive, and shipbuilding, where corrosion resistance and strong welds are essential. Below, we will explore the key advantages of using stainless steel flux cored welding wire.

One of the most prominent advantages of stainless steel flux cored welding wire is its excellent corrosion resistance. The flux inside the wire enhances the weld pool's protection from atmospheric elements like oxygen and moisture, which can degrade the quality of welds made with traditional welding wires. Stainless steel, as a material, is inherently resistant to rust, oxidation, and corrosion, making it an ideal choice for applications where longevity and durability are critical.

This characteristic is particularly beneficial for welding in harsh environments such as marine, chemical, or food processing industries. The ability to resist corrosion ensures that the welded joints maintain their integrity over time, reducing the need for maintenance or repairs.

Stainless steel flux cored welding wire is engineered to provide strong, high-quality welds. When used properly, the wire creates robust joints with high tensile strength, which are essential in structural and load-bearing applications. The high deposition rate of flux cored wire ensures the weld bead is filled efficiently, minimizing any chances of weakness in the final weld. Additionally, the wire's high arc stability allows for smooth and consistent welds with minimal spatter.

The mechanical properties of stainless steel flux cored welding wire ensure that the welded joint maintains its strength, even under extreme temperatures or stress. This makes it ideal for use in demanding sectors, such as the construction of pressure vessels or pipelines, where strength and durability are of paramount importance.

Another significant advantage of stainless steel flux cored welding wire is its ease of use and high welding efficiency. Unlike traditional solid wires, flux-cored wires are designed to self-shield or require less shielding gas, which reduces operational costs and simplifies the welding process. The presence of flux also helps in cleaning the weld area by removing impurities, resulting in smoother, cleaner welds.

The ease of handling and versatility of stainless steel flux cored welding wire make it suitable for both novice and experienced welders. Additionally, the wire’s ability to be used in a variety of positions (flat, horizontal, vertical, and overhead) further enhances its convenience and efficiency in different welding applications.

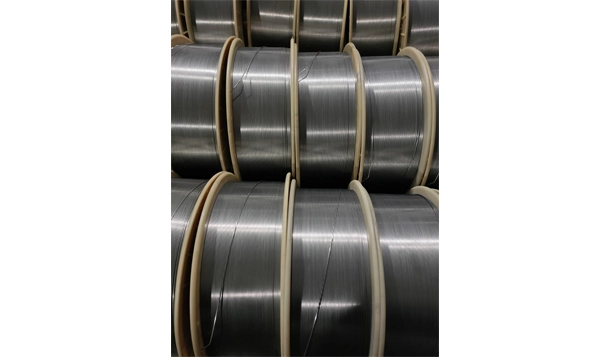

While stainless steel flux cored welding wire may have a higher initial cost compared to other welding wires, it offers substantial long-term savings. The high efficiency, reduced need for shielding gases, and increased productivity directly contribute to lowering overall operational costs. Additionally, the corrosion-resistant properties of stainless steel ensure that the welded parts last longer, requiring fewer repairs or replacements.

In many cases, the long-lasting performance of stainless steel flux cored welding wire means that it is a more cost-effective solution than other types of welding wire, particularly for projects requiring long-term durability.

| Feature | Advantage |

|---|---|

| Corrosion Resistance | Superior resistance to rust, oxidation, and wear |

| Weld Strength | High tensile strength and durability |

| Ease of Use | Simplified welding process with reduced gas needs |

| Cost-Effectiveness | Long-term savings due to durability and efficiency |

In conclusion, stainless steel flux cored welding wire offers a range of advantages that make it an excellent choice for professional welders and industries requiring high-performance materials. Its exceptional corrosion resistance, weld strength, ease of use, and cost-effectiveness make it a versatile and reliable option for various applications. By choosing stainless steel flux cored welding wire, welders can ensure quality and longevity in their work, even in the harshest environments.