Features

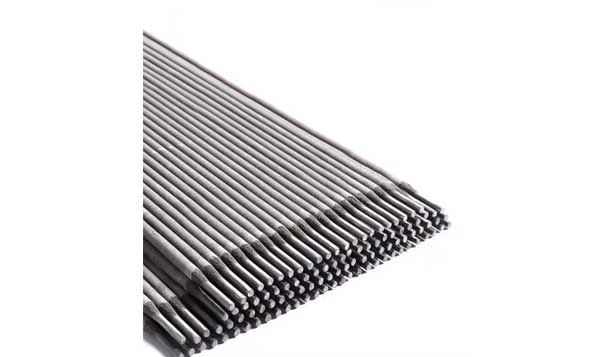

E7016-G has good atmospheric corrosion resistance.

It also has good mechanical properties and crack resistance.

It is applicable to welding carbon steel and weathering steel structures with tensile strength of 490MPa.

Minghua brings you high-quality welding consumables China, featuring different types of electrodes in welding.

Chemical Composition

| Chemical components of deposited metal (%) |

| Test item | C | Mn | Si | S | P | W | Cu |

| Example value | 0.066 | 0.84 | 0.21 | 0.007 | 0.016 | 0.3 | 0.36 |

| Reference current (AC, DC+) |

| Welding electrode diameter (mm) | Φ3.2 | Φ4.0 | Φ5.0 |

| Welding current(A) | 90-130 | 150-190 | 180-230 |

E7016 Welding Rod Uses

The E7016 welding rod, a low-hydrogen electrode for shielded metal arc welding (SMAW), is versatile across various industries due to its high strength and crack resistance. It excels in

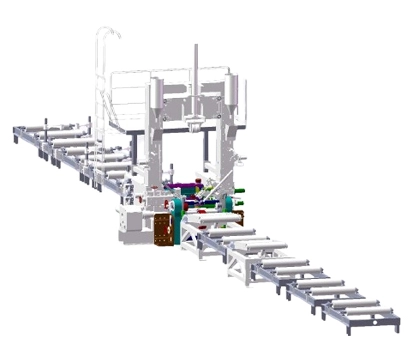

pressure vessel welding, producing reliable welds for carbon and low-alloy steel vessels like boilers, ensuring durability under high-pressure conditions. In

metallurgy welding, E7016 is used to fabricate robust steel components, delivering excellent toughness for industrial structures. For aircraft welding, it provides precision welds for critical aerospace parts, such as landing gear, meeting stringent safety standards. In automotive applications, E7016 supports

car welding machine for repairing or building steel chassis, offering strong and consistent welds. Additionally,

welding on a ship benefits from E7016’s ability to create corrosion-resistant welds for ship hulls and offshore structures, ensuring longevity in harsh marine environments. Proper storage is crucial to maintain its low-hydrogen properties for optimal performance.

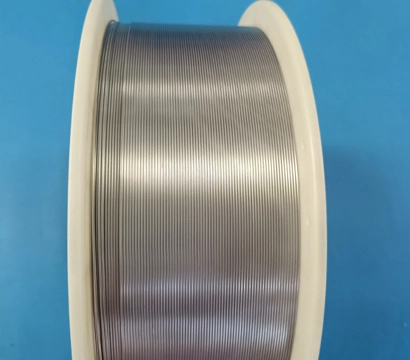

Other Welding Consumables & Equipment You May Also Like