H Steel Beam Production Line

Welding straightening machine is a special equipment that directly assembles, welds and corrects the wing plate and web plate of H-shaped steel. This advanced steel beam welder integrates multiple functions to optimize the production process.

The process that is traditionally completed by three equipment, such as assembling machine, gantry welding machine and straightening machine, is concentrated in one equipment, significantly improving production efficiency. This all-in-one steel beam welder reduces equipment costs, saves space, and conserves human and material resources and electricity. It is a highly efficient production equipment for H-shaped and T-shaped steel.

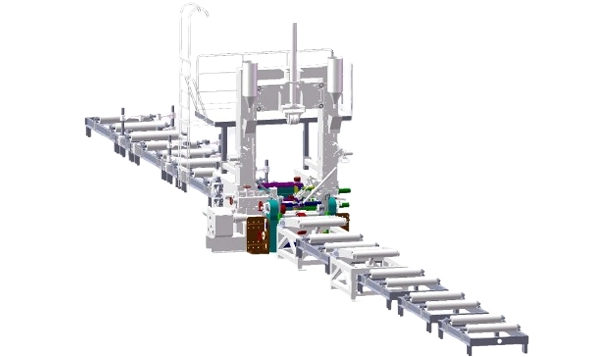

The equipment consists of welding assembly main machine, straightening auxiliary machine, pre-centering system, active roller table, passive roller table, flux recovery system, hydraulic system, electric control system, welding power supply, and other components, making it a comprehensive steel beam welder solution. As one of the leading auto welding machine manufacturers, Minghua is ready to offer solutions tailored to your needs.