Key Applications

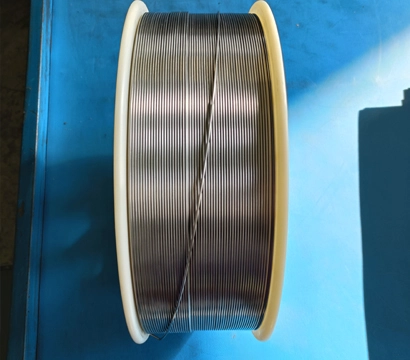

Thick Materials: Flux core welding wire excels in welding thick materials due to its ability to deposit more weld metal per unit of time and achieve greater penetration compared to methods like MIG welding.

High Deposition Rates: The high deposition rate of flux core welding wire allows for faster welding, making it advantageous in time-sensitive projects.

Out-of-Position Welding: Thanks to the flux-based shielding, flux core welding can be performed in various positions, including overhead and vertical.

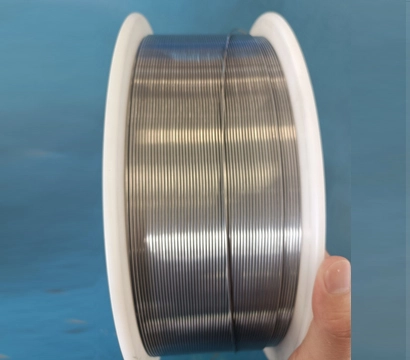

Versatility: This welding wire can be used on a wide range of materials, including mild steel, stainless steel, high-nickel alloys, and low-alloy steels.

Industry-Specific Uses

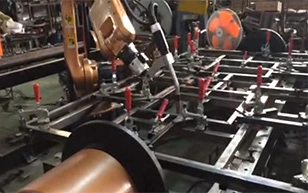

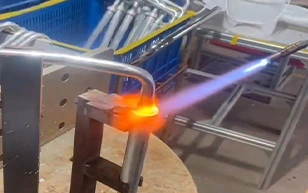

Automotive Parts Welding: The deep penetration capability of flux core welding wire makes it suitable for welding automotive parts, especially where strong joints are required.

Agricultural Equipment Repair: In agricultural equipment maintenance, flux core welding wire effectively handles surfaces that may have rust or oil, making it ideal for repair work.

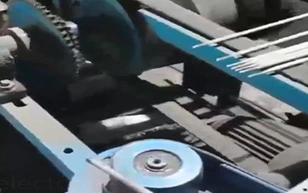

Construction: Due to its high penetration, flux core welding wire is commonly used in construction for heavy-duty connections, such as welding steel structures.

Pressure Vessels and Petrochemical Pipelines: Suitable for heavy industry and petrochemical applications, it can withstand high temperatures and pressures.